Form Up Slabs With Ceiling Frames

On balance the most desirable floor material is concrete when durability, stability, acoustic and thermal properties are considered. There is a cost above some alternatives and in most cases the need for full masonry construction to support it.

Subsequent to the traditional Smartslab system, we have developed a new and alternative Kitformwork. The new system is quite revolutionary and obliges the Occupational Health and Safety requirements, eliminating any temptation to drop form-work as it is stripped – minimising risk. Kitformwork continues with the advantages that a ceiling frame configuration set under the slab offers but incorporates traditional reinforced slab design. There are some projects where very large spans, high loads and fire ratings, acoustic considerations or simply personal preference may affect that choice.

| Click thumbnails for slideshow | |||

|---|---|---|---|

|

|

|

|

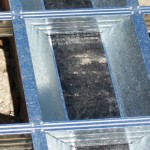

Kitformwork begins with a steel frame much the same as with Smartslab, but using 100mm joists spaced at 600 mm centres to accept traditional plasterboard linings. Metal sheeting is then fixed to the top of the joist frame and 60 % less propping is needed to support concrete and construction loadings. Wherever a load bearing wall is required, plates are fixed to direct concrete to flow down to it. Around the perimeter, special brackets which become imbedded in the concrete hold edge boards which are later removed. The reinforcing steel is placed according to conventional design and the concrete is poured. When a normal curing time has elapsed any propping is removed but the frame under the concrete remains. This frame negates any need for battening out or fixing false ceilings so often an additional cost in slab construction. Similar to Smartslab, services may now be run. Recessed lighting and plumbing between and through the frame are easily fixed.

This metal formwork is placed very quickly assembled on site or alternatively installed as pre-made panels up to 35 m2 in area, a great time saving advantage for builders. The finish is not dependent on the individual form-worker but upon the system. All joists are supplied cut to length along with a layout detail. The cost is very competitive with current formwork but includes a ceiling frame. Later stripping is very simple involving the removing of a few props. Edge boards are removed on the day of pour and the frame is sacrificial formwork.

Unlike traditional formwork, trade work can begin under the slab the day after the pour, and it is quite possible that render or other internal wall finishes may be installed prior to removing the props, as they are at least 2 metres from any wall face.

Smartslab Pty Ltd, as well as supplying a complete service, does offer kits of materials for the builder or formworker to assemble for themselves. The projects that have been completed to date have been a huge success, saving considerable time, providing options for other service contractors not previously possible and allowing a dead flat ceiling to be readily fixed. The day after the pour there is room under the slab for a continuation of work and undercover site storage of building materials. Smartslab are always ready to respond with an obligation free and comprehensive quotation and where appropriate a site visit to discuss your requirements.